In the Industrial IoT (IIoT) world, which is always changing, correct and trustworthy data is essential for running processes smoothly. Flow meters are one of the most important parts of industrial infrastructure. They measure how fast fluids move through pipes in fields like oil and gas, water treatment, and chemical processing. Traditional flow meters, on the other hand, often don’t work well in harsh environments, which can cause wrong readings, high repair costs, and downtime.

ML physics modeling for hybrid virtual flow meters is a big step forward because it blends machine learning (ML) with physics-based simulations to make smart, flexible flow monitoring systems. This mixed method is changing how industrial systems measure, analyze, and react to fluid dynamics in real time, making them much better at what they do, more accurate, and less expensive.

The Limits of Conventional Flow Meters

Traditional flow meters, whether mechanical, ultrasonic, or electromagnetic, rely heavily on physical instrumentation placed directly within the pipeline. Most of the time, these devices need to be calibrated on a regular basis. They also wear out over time and can be wrong when flow rates change or when pressure and temperature levels change. In complex or remote industrial environments, physical maintenance is both costly and risky.

Moreover, static flow meter models do not adapt to process changes over time. Any deviation from calibrated conditions can result in significant measurement errors—impacting not only operational efficiency but also safety and compliance.

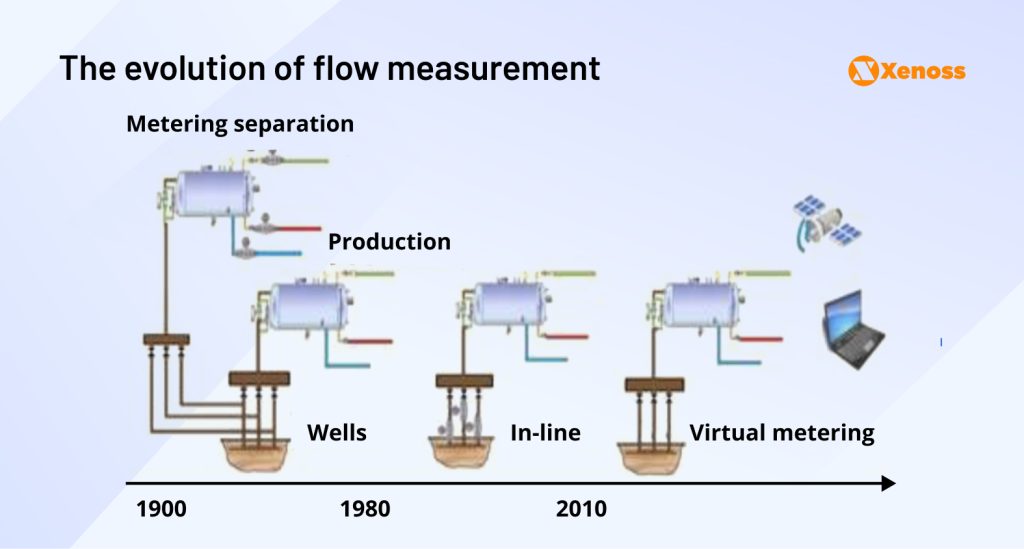

Virtual Flow Meters: The First Step Forward

The idea of virtual flow meters was created to solve these problems. These software-based tools simulate flow behavior using known physical laws and process data from sensors installed along the pipeline. By reducing reliance on physical instrumentation, virtual flow meters lower maintenance requirements and offer better adaptability.

However, purely physics-based virtual models also have limitations. They require precise knowledge of all system parameters, and their accuracy may degrade when dealing with real-world uncertainties such as sensor noise, equipment aging, or unknown system variables.

Hybrid Modeling: The Best of Both Worlds

This is where hybrid virtual flow meters ml physics modeling takes center stage. By integrating physics-based simulations with data-driven machine learning models, hybrid virtual flow meters offer a powerful, flexible, and self-adaptive solution.

Here’s how it works:

- Physics-Based Component: Models built on fluid dynamics and thermodynamics provide a solid foundation rooted in engineering principles. These models define the expected flow behavior based on known inputs and system design.

- Machine Learning Component: ML models learn patterns and anomalies from historical and real-time sensor data. They compensate for unknowns, noise, and non-linear behaviors that traditional physics models struggle to capture.

When combined, the hybrid model dynamically updates itself as new data arrives, refining its predictions for improved accuracy and robustness. This dual-layered approach ensures the system remains reliable even under unpredictable operational conditions.

Benefits of Industrial IoT Applications

The integration of hybrid virtual flow meters and ML physics modeling into industrial IoT systems brings numerous benefits:

1. Enhanced Accuracy

Hybrid models reduce measurement errors by addressing both known physical factors and data-driven uncertainties. This is particularly useful in processes with fluctuating flow rates, pressure drops, or mixed-phase fluids.

2. Lower Operational Costs

By minimizing dependency on physical sensors and reducing maintenance needs, hybrid virtual flow meters help lower operational costs over time. Predictive maintenance based on ML insights further optimizes asset management.

3. Real-Time Monitoring and Adaptability

These models can continuously learn from live data, enabling real-time monitoring and proactive adjustments to system operations. This adaptability is vital for optimizing throughput and ensuring safety.

4. Scalability and Remote Deployment

Because virtual and hybrid models are software-driven, they can be deployed across multiple sites with minimal physical infrastructure. Because of this, they are perfect for places that are hard to reach or dangerous and where regular flow meters would be hard to maintain.

Conclusion

Hybrid modeling for flow meters represents a pivotal advancement in the realm of industrial IoT. By combining the rigor of physics with the flexibility of machine learning, hybrid virtual flow meters’ ML physics modeling is setting a new standard for intelligent, reliable, and scalable flow measurement.

Businesses are under more and more pressure to be more eco-friendly and efficient. To stay ahead in the digital transformation of industrial processes, they will need to use hybrid models.